The research, creation, and use of materials and tools ranging in size from 1 nanometer to 100 nanometers are all part of nanotechnology. At this size, the properties of the material are very different from those of bulk materials. For example, they are stronger, lighter, and conduct electricity and heat better. Because they are so different, nanomaterials are useful in many manufacturing processes, from electronics to aerospace.

By changing materials at the nanoscale, nanotechnology can create products with better performance and more functions. This can improve material properties, increase production efficiency, and create new products that cannot be made using traditional manufacturing methods.

1. Better Material Performance

Better material properties are one of the most important implications of nanotechnology for manufacturing. Nanomaterials can differ in mechanical, thermal, and electrical properties from bulk materials. For example, nanocomposites consist of nanomaterials mixed in a matrix and are extremely strong and durable, yet lightweight. This is especially useful in areas such as aerospace and automotive, where strong, yet lightweight materials are important.

In addition, nanotechnology makes it possible to create materials that conduct heat and electricity better. Nanomaterials such as graphene and carbon nanotubes are very good at conducting electricity, making them ideal for use in electronics and thermal management. By using these materials in the manufacturing process, companies can create electronic devices and components that perform better and last longer.

2. Better Manufacturing Methods

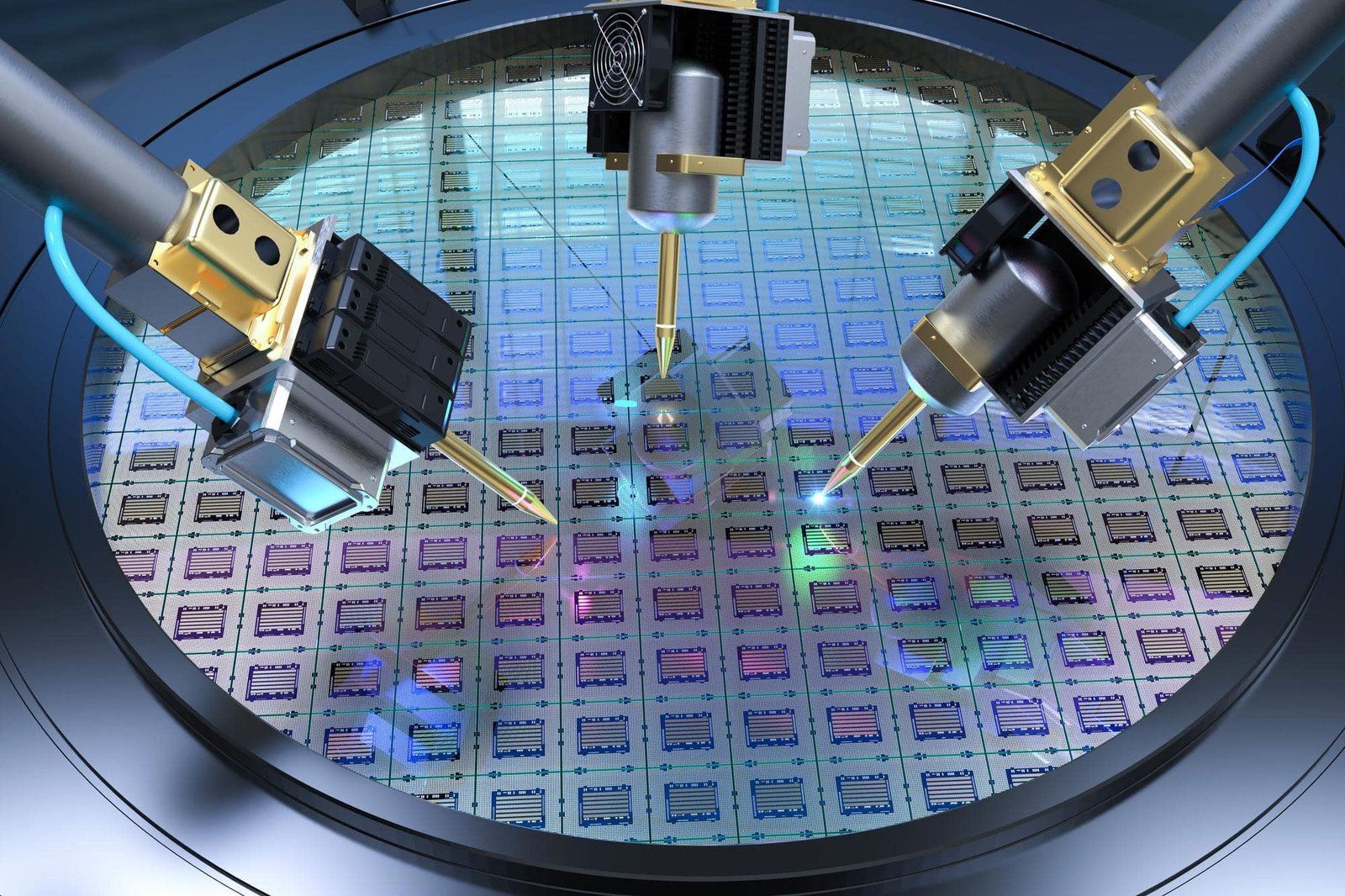

Nanotechnology has also made significant improvements in the way things are made. Nanomaterials can make processing more precise and controllable, making manufacturing methods more efficient. Nanoscale films and coatings can be precisely placed on surfaces to make them better, for example by reducing rust or making them less likely to stick together. Methods such as atomic layer deposition and molecular beam epitaxy make it possible to control things at this level. These methods deposit thin layers of nanomaterials with atomic precision.

Nanotechnology has also given rise to more advanced manufacturing methods, such as nanoimprint lithography and self-assembly. These technologies make it possible to fabricate complex patterns and structures on a nanometer scale, allowing components to be manufactured with unprecedented levels of detail and functionality. In the electronics and semiconductor industries, where small dimensions and precision are important, this type of technology is very useful.

3. New Ideas for Product Manufacturing

As nanotechnology is used in manufacturing, new products are emerging that push the boundaries of what is possible. Nanotechnology makes it possible to create flexible electronics, such as bendable displays and wearable sensors. This is achieved by adding nanomaterials to electronic components. These new ideas open up new possibilities for consumer electronics and medical devices, making them more flexible and useful.

Nanotechnology has helped create better drug delivery systems and diagnostic tools than ever before. Nanoparticles can be designed to deliver drugs directly to the cells or tissues that need them, making treatment more effective and having fewer side effects. Nanoscale sensors can also be used for highly sensitive and accurate diagnostic tests, allowing for earlier detection and better treatment of diseases.

4. Lifespan and Environmental Impact

Using nanotechnology also helps make the manufacturing process more environmentally friendly. Nanotechnology can make manufacturing more environmentally friendly by making processes more efficient and reducing waste. For example, using nanomaterials in catalytic processes can make chemical reactions more efficient, meaning they use less energy and produce fewer pollutants.

In addition, nanotechnology can help solve environmental problems by creating more advanced technologies for cleaning and filtering waste. Nanomaterials can be used to create very good filters that clean air and water by removing pollutants at the nanoscale. This skill is especially useful in dealing with problems such as pollution and resource management.

5. Current Problems and Future Plans

Nanotechnology has many advantages for manufacturing, but some issues need to be addressed. One of the biggest issues is that creating and combining nanomaterials is expensive and difficult. The need for specialized equipment and knowledge, as well as the high research and development costs, can make this inaccessible to many.

In addition, the potential hazards of nanomaterials need to be carefully studied, such as how they can affect human health and the environment. Ensuring safe handling and disposal of nanomaterials is important to reduce risks and get the most out of nanotechnology.

Conclusion

Nanotechnology is changing the way things are made by improving material properties, improving manufacturing processes, and enabling the creation of new products. Nanomaterials have special properties that make them very useful. For example, they are stronger, conduct electricity better, and can be machined more precisely. As research and development in nanotechnology continue to advance, it has the potential to change the way things are made and drive innovation in many areas. Nanotechnology offers many opportunities. Its use will lead to a future of manufacturing that is more efficient, sustainable, and capable of creating revolutionary products.

FAQs

1. What does nanotechnology mean?

Nanotechnology is the study and manipulation of materials at the atomic and molecular level, typically between 1 and 100 nanometers. Materials of this size have different physical and chemical properties than their bulk counterparts. This allows for the creation of new materials and technologies that work better and are more versatile.

2. What impact does nanotechnology have on manufacturing?

Nanotechnology is transforming manufacturing by improving material properties, improving manufacturing processes, and enabling the creation of new products. Nanomaterials have unique properties, such as being stronger, better conductors of electricity, and easier to work with. These qualities can make manufacturing processes and products more efficient and effective.

3. What types of nanomaterials are used in manufacturing?

Nanomaterials such as carbon nanotubes, graphene, metal oxides, and nanoparticles are commonly used in manufacturing. Metal oxides, such as titanium dioxide and manganese dioxide, are used to improve the properties of many different materials. Carbon nanotubes and graphene are known for their excellent electrical conductivity and mechanical strength.

4. How do nanomaterials improve the performance of things?

Nanomaterials improve the performance of materials by giving them a larger surface area to interact with, increasing their strength, and making them better conductors of heat and electricity. For example, nanocomposites can be stronger and lighter than regular materials, while nanomaterials like graphene may be better at transporting electricity than bulk materials.

5. What are the benefits of using nanotechnology in manufacturing processes?

Nanotechnology improves manufacturing by making processing more precise and controlled. Nucleic acid beam epitaxy and atomic layer deposition are two techniques that can deposit very thin layers of nanomaterials with atomic precision. This improves surface properties, reduces friction, and makes the manufactured part work better overall.